SMT焊接不良及图片说明9--Wicking(灯芯效应)

日期:2009-12-07 21:26 点击:3329

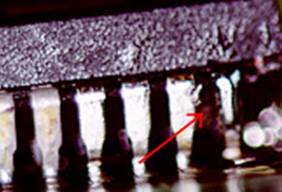

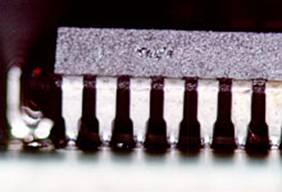

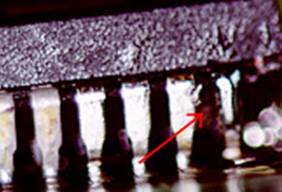

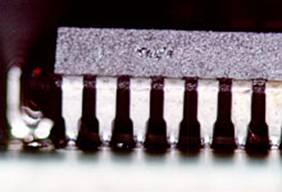

9.Wicking(T心效)

拒收 良好情r

缺c描述 :

Solder has been drawn up on the lead of a component.The copper pad has little or no solder.

PROBABLE CAUSES

- Solderability problem with the copper pad

- Deposition of too much solder paste

- Contamination of solder pad

|

- Make sure that there is enough solder deposition on the solder pad

|

POSSIBLE PREVENTIONS

- Improve solderability of pad

- Use component with clean leads as saturation prevents solder being drawn up

- Check the squeezee and stencil of the solder printing machine regularly to make ensure that correct amount of solder paste is printed on the PCB

|

- Coat upper part of lead with solder resist so that solder will not be drawn up the lead.

- Use differentiating solder paste with varying temperature.

|

REWORK

Wicking can be removed by touching it with a well-tinned tip of soldering iron.