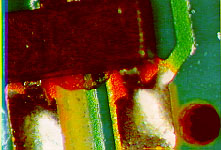

10.Nonwetting(未)

拒收 良好情r

缺c描述 :

The failure of the metal surface to be wetted by the molten solder when using the flux. The original metal surface remains intact.

零件_金俦砻姹3衷有的外形 , 而助焊└焊接失〉腻ac像T模一@在外

可能因素 :

- Solder temperature too low

- 焊a囟冗^低 - a未克服表面力c零件_接合

- Solder is contaminated

- 焊a污染 - 熔c高 , 熔接能力差

- Preheat temperature too low

- A囟冗^低 - 焊r崛萘坎蛔

- Flux is contaminated

- 助焊┪廴 - 失去活化或窆δ

- Flux no longer active

- 助焊┪赐耆活化 - A囟炔徽_ , 不o法l]助焊力

- Board rerun

- 板子重新焊 - a球表面氧化 , 助焊┱舭l

- Component contamination

- 零件_表面污染 - 氧化 , 作I人T接|留下油脂 , 作I溶┗蛄慵_表面理溶留

- Board contamination due to insufficient board cleaning

- 基板表面不或污染 - 氧化 , 作I人T接|留下油脂 , 作I溶┗蚧板表面理溶留

- Board oxidized due to insufficient preflux protection

- 焊接前保o不足 , 基板氧化 - Υ孢^久 , 或Υl件不良

可行的A防方法 :

- Increase the temperature of the solder

- 增加焊接囟 - _保熔接峰值囟仍 210-230 ℃

- Prevent the solder from contamination

- 防止焊a氧化 - 合理的胤绞 , m的操作h境c使用rg

- Increase the preheat temperature

- 增加A囟 - 增加均^的崛萘 , 使焊熔a利M行

- Check for flux contamination

- _J助焊┪廴 - 避免酒精 , 去K油 , 或板清溶┪廴

- Keep track with the concentration of the flux to maintain the reactivity of the flux

- _保助焊┐_活化 - 依a膏格{整均^曲

- Ensure that the board is placed evenly before soldering

- _保基板非重覆^t - 未完全熔a的板子重^添加助焊

- Components’ lead or solder portions should be free from contamination

- 零件_表面_]有污染 - M料沾az , cm的Υ , 避免作Ic接|污染

- Proper handling of the board will prevent the protective layer to be wear off

- 正_的操作基板避免表颖Wo适 - M料沾az , cm的Υ , 避免作Ic接|污染

- Board should not be kept too long exceeding the period whereby the protective coating is wear off

- 基板保存期限勿^久使表颖Wo适 - m的Υ , 及使用前的除 , 原B化作I

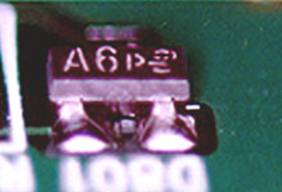

REWORK

The joint is soldered back by placing the chisel-shaped soldering tip against it long enough such that the transfer of heat is sufficient enough before placing the solderwire close to the tip of the iron.