2.Disturbed/Fractured Solder Joint( 不t / 嗔训腻ac )

拒收 良好情r

缺c描述 :

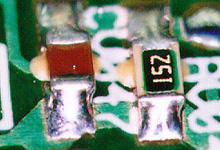

It is characterized by stain marks and dull color on the surface or by a rough gritty appearance.

PROBABLE CAUSES

|

|

POSSIBLE PREVENTIONS

|

|

REWORK

Disturbed solder joint is desoldered with the help of a chisel-shaped soldering tip and solder wick.The solder wick should be pressed into the corner long enough to let the heat travel into the gap underneath the component so that the solder is sucked out.The joint is resoldered back by placing the solder iron against it long enough such that the transfer of heat is sufficient enough before placing the solderwire close to the tip of the iron.